Introduction to Boiler Plates

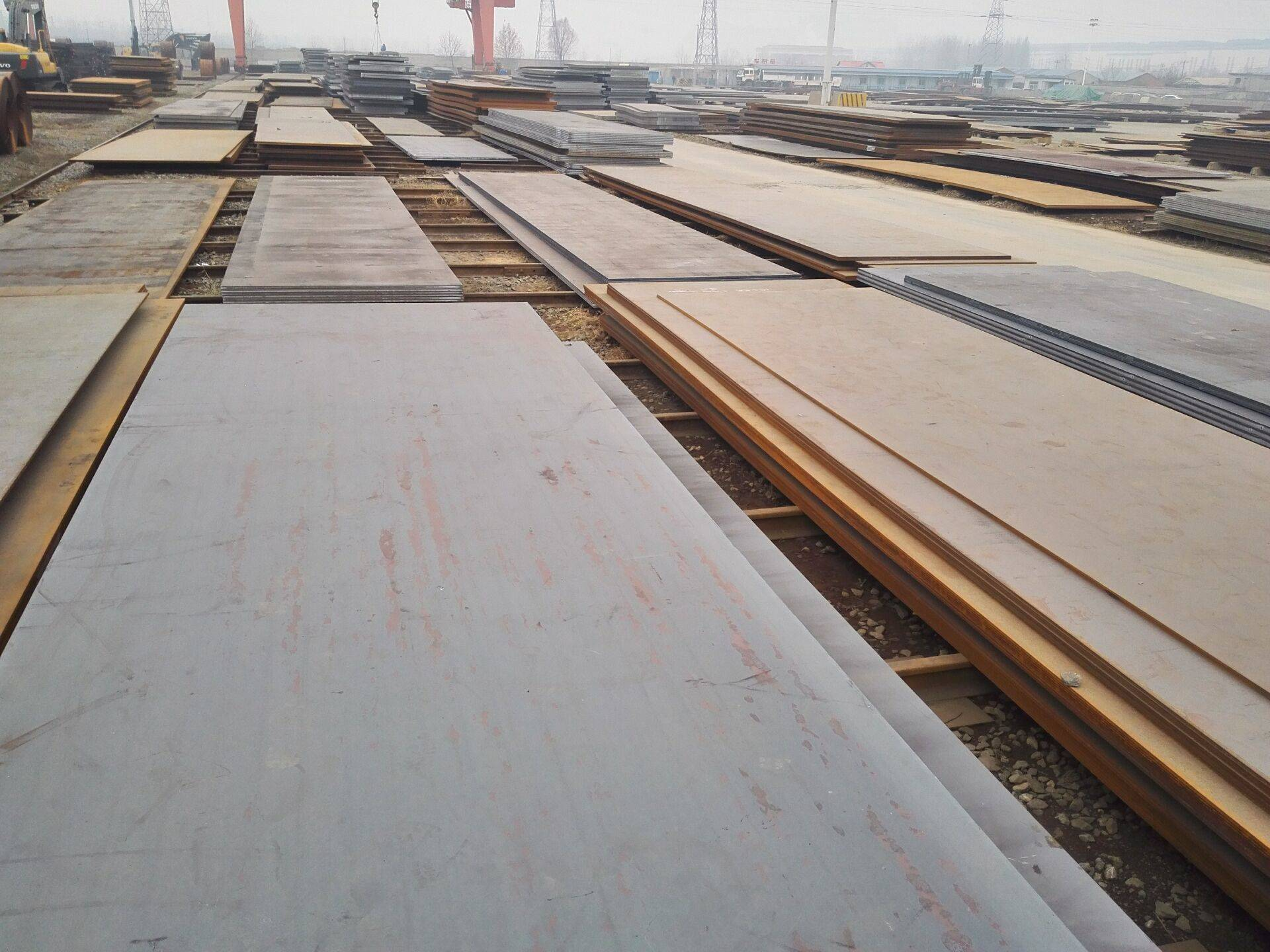

When it comes to industrial applications, the term “boiler plate” often comes up in discussions about steel plates. Boiler plates are a specific type of carbon steel plate designed to withstand high pressure and temperature, making them essential in the manufacturing of boilers and pressure vessels. Jindalai Steel Group Co., Ltd., a leading boiler plate manufacturer, specializes in producing high-quality boiler plates that meet stringent industry standards. But what exactly sets boiler plates apart from ordinary steel plates?

The Production Process: Boiler Plate vs. Ordinary Steel Plate

The production process of boiler plates differs significantly from that of ordinary steel plates. While both types of plates start with raw steel, the treatment and specifications for boiler plates are much more rigorous. Boiler plates undergo a series of processes, including controlled rolling and heat treatment, to enhance their strength and durability. This ensures that they can handle the extreme conditions they will face in applications such as power plants and chemical processing facilities. Ordinary steel plates, on the other hand, may not undergo such stringent processes, making them less suitable for high-pressure applications.

Application Scenarios of Boiler Plates

Boiler plates are not just any steel plates; they are the backbone of various industrial applications. From power generation to oil and gas extraction, these plates are used in environments where safety and reliability are paramount. They are commonly found in boilers, pressure vessels, and heat exchangers, where they must withstand high temperatures and pressures. The versatility of boiler plates makes them indispensable in industries that require robust materials capable of enduring harsh conditions. Jindalai Steel Group Co., Ltd. has established itself as a trusted boiler plate producer, supplying these essential materials to various sectors.

Boiler Plate Processing and Production Technology

The processing and production technology of boiler plates have evolved significantly over the years. Advanced techniques such as automated welding, precision cutting, and non-destructive testing are now standard in the industry. These technologies ensure that every boiler plate produced meets the highest quality standards. Jindalai Steel Group Co., Ltd. employs state-of-the-art machinery and skilled technicians to ensure that their boiler plates are not only compliant with industry regulations but also exceed customer expectations. This commitment to quality is what sets them apart in the competitive market of steel plate manufacturing.

The Future of the Boiler Plate Market

As industries continue to innovate, one might wonder if the boiler plate market will be replaced by newer materials or technologies. While advancements in materials science may introduce alternatives, the unique properties of boiler plates—such as their ability to withstand extreme conditions—ensure that they will remain relevant for the foreseeable future. The demand for boiler plates is expected to grow, particularly in emerging markets where industrialization is on the rise. Jindalai Steel Group Co., Ltd. is well-positioned to meet this demand, continuing to produce high-quality boiler plates that are essential for modern industry.

In conclusion, understanding the nuances of boiler plates, from their production processes to their applications, is crucial for anyone involved in industrial manufacturing. With companies like Jindalai Steel Group Co., Ltd. leading the way, the future of boiler plates looks bright, ensuring that they will remain a vital component in various industries for years to come.

Post time: Aug-17-2025