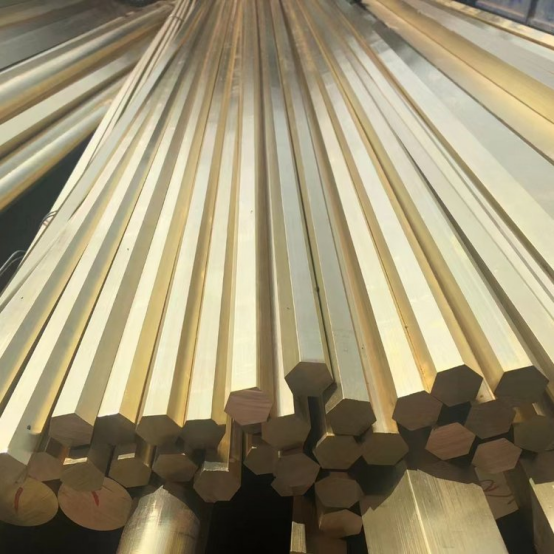

Why Hexagonal? The Shape That Rocks!

When it comes to metal bars, you might think round or square is the way to go. But let me tell you, hexagonal bars are the real MVPs! Why, you ask? Well, they’re like the Swiss Army knife of the metal world. Hexagonal shapes provide superior grip for wrenches, preventing those pesky rolling incidents that can turn a simple project into a game of “Where Did My Tool Go?” Plus, they’re perfect for assembly with nuts and joints, making them a go-to choice for engineers and DIY enthusiasts alike. So, if you’re looking to up your game in material utilization, brass hexagonal bars from Jindalai Steel Group Co., Ltd. are your best bet!

Finishing Touches: Making Metal Shine!

Now, let’s talk about surface finishes. You might think that a bar is just a bar, but oh, how wrong you are! Common finishes like brushing, polishing, and hot forging can transform a plain brass hexagonal bar into a stunning piece of art. Not only do these finishes enhance the aesthetic appeal, but they also extend the functional value. For instance, nickel plating and chrome plating can provide corrosion resistance, while passivation can improve the longevity of your brass hexagonal bar. So, whether you’re crafting a masterpiece or just need something functional, don’t underestimate the power of a good finish!

Manufacturing Magic: How It’s Made!

Ever wonder how those beautiful brass hexagonal bars come to life? The magic happens through various manufacturing processes like extrusion, drawing, and continuous casting. Each method has its own flair, affecting everything from dimensional accuracy to grain structure. For instance, extrusion can create long, uniform bars, while drawing can enhance the mechanical properties. So, when you’re choosing your brass hexagonal bar, remember that the process behind it can make all the difference in quality and performance. Jindalai Steel Group Co., Ltd. knows how to get it right!

Machining Madness: Tips for Success!

Alright, let’s get down to the nitty-gritty of machining brass hexagonal bars. It’s not just about grabbing a tool and going to town; there’s a bit of finesse involved. First off, tool selection is crucial—using the right tool can save you time and headaches. Then there’s cooling and lubrication; you don’t want your tools overheating and throwing a tantrum! And let’s not forget about chip handling—nobody wants a mess on their hands. By considering these factors, you can optimize efficiency and maintain dimensional stability, ensuring your brass hexagonal bars are machined to perfection.

The Jindalai Advantage: Quality You Can Trust!

At the end of the day, when you’re in the market for brass hexagonal bars, you want a manufacturer you can trust. Jindalai Steel Group Co., Ltd. stands out with its commitment to quality and innovation. With a range of products including brass hexagonal bars, brass bars, and hexagonal copper bars, they’ve got you covered. So, whether you’re a seasoned pro or a weekend warrior, remember that choosing the right materials is key to your success. Go ahead, embrace the hexagonal revolution, and let Jindalai Steel Group Co., Ltd. be your partner in metal fabrication!

Post time: Dec-16-2025