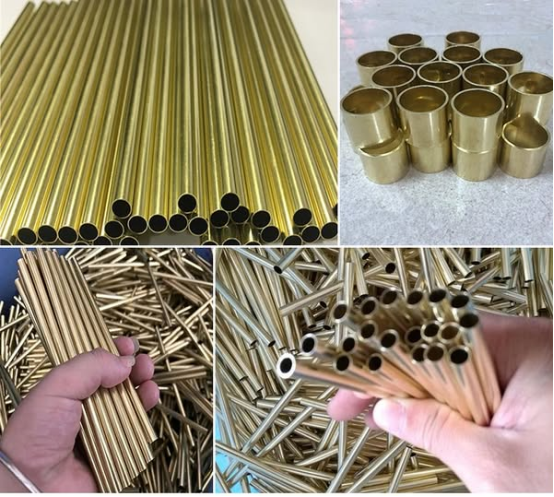

Welcome to the world of brass tubing, where gleaming metal and practicality blend perfectly! If you’ve ever wondered about the difference between H62 and H65 brass tubing, or simply want to understand why Jindalai Steel Group is your preferred brass tubing supplier, then this is for you. Grab your favorite beverage and let’s explore the shimmering world of brass together!

H62 vs. H65 Brass Tubing: A Showdown

First, let’s compare two types of brass tubing: H62 and H65. Both are common choices for brass tubing manufacturers, but there are differences between them. H62 brass tubing is known for its excellent corrosion resistance and good machinability, making it ideal for applications requiring durability. On the other hand, H65 brass tubing has a higher copper content, which makes it stronger and gives it a slightly different color. You can think of H62 as a reliable friend who always arrives on time, while H65 is an adventurous partner who is always eager to take on challenges.

Everyday Scene: Brass Pipes Shine Brightly

Now, you might be wondering, “Where exactly are these brass tubes used?” Let me tell you, they’re everywhere! From plumbing to electrical applications, brass tubes are the unsung heroes that silently contribute to our daily lives. Looking to build a sturdy frame for your new bicycle? Brass tubes are definitely the way to go! Want to add a touch of elegance to your home décor? Polished brass tubes can do the trick! They’re also commonly found in musical instruments, adding a unique charm to their beautiful tone. So, the next time you hear a trumpet, remember: it’s all thanks to brass tubes!

Corrosion Resistance: Humidity Test

Now, let’s talk about a question that might keep you up at night: corrosion resistance. You might be wondering, “Can brass tubing withstand humid environments?” The answer is yes! Brass tubing, especially precision-manufactured brass tubing, has excellent corrosion resistance, making it ideal for hot summers and even coastal areas. So, if you’re worried that your brass tubing will rust like last year’s beach towels, don’t worry! They’re durable.

What’s inside the markings? The mystery of 10 x 1 millimeters.

You might have seen brass tubing marked “10 x 1mm” and wondered, “What does that mean?” Don’t worry, friend, it’s not some secret code! This marking refers to the tubing’s outer diameter and wall thickness. In this example, the outer diameter is 10 millimeters, and the wall thickness is 1 millimeter. It’s like the brass tubing is saying, “Hey, I’m small but strong!”

Welding Challenge: Can brass pipes be welded?

Finally, let’s answer the question everyone is most concerned about: Can ordinary brass pipes be directly welded? In short: not really. Brass becomes brittle when heated, which can lead to serious problems during welding. However, with the right techniques, a skilled welder can still connect brass pipes. Just remember, if you’re not a welding expert, it’s best to leave it to a professional.

Conclusion: Brass tubing wins!

Alright, that’s it! Whether you need precision seamless brass tubing or simply want to understand the difference between H62 and H65, Jindalai Steel Group has you covered. They offer a complete range of brass tubing, including polished types, so you’re sure to find the ideal product for your next project. So, let’s raise a glass (or raise a brass tube) to the unsung heroes who quietly contribute to everyday life! Cheers!

Post time: Nov-14-2025