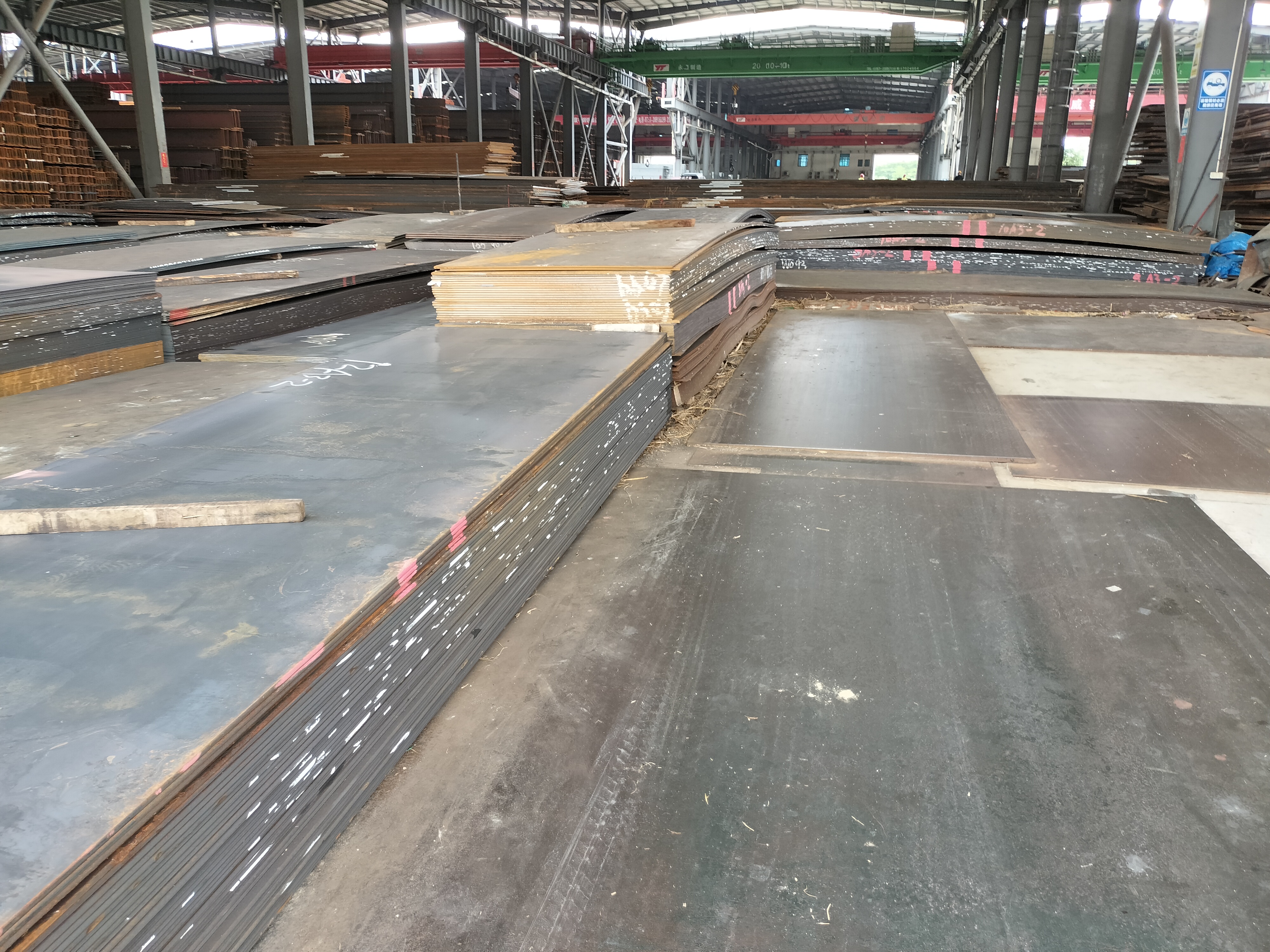

Understanding Carbon Steel Plates

Carbon steel plates are essential components in various industries, serving as the backbone of modern manufacturing. Produced by carbon steel plate manufacturers like Jindalai Steel Group Co., Ltd., these plates come in different forms, including hot-rolled and cold-rolled steel plates. The production process of carbon steel plates involves heating steel to high temperatures and then rolling it into flat sheets. Hot-rolled steel plates are typically produced at temperatures above 1,700°F, while cold-rolled plates are processed at room temperature, resulting in a smoother finish and tighter tolerances. This versatility makes carbon steel plates a popular choice for construction, automotive, and machinery applications.

Practical Applications of Carbon Steel Plates

The practical applications of carbon steel plates are as diverse as the industries that utilize them. From structural components in buildings to parts in heavy machinery, these plates are indispensable. They are often used in the manufacturing of bridges, ships, and pipelines, showcasing their strength and durability. Additionally, carbon steel plates are favored in the automotive industry for producing chassis and body panels due to their excellent weldability and formability. So, whether you’re building a skyscraper or a sports car, you can bet that carbon steel plates are playing a crucial role in the process.

Thin Gauge Limit for Carbon Steel Plates

When it comes to carbon steel plates, thickness matters. The thin gauge limit for carbon steel plates typically starts at around 0.5 mm and can go up to several inches thick, depending on the application. Thin gauge plates are often used in applications where weight savings are critical, such as in aerospace and automotive industries. However, it’s essential to strike a balance between weight and strength, as thinner plates may not provide the necessary structural integrity for certain applications. Therefore, understanding the specific requirements of your project is crucial when selecting the appropriate gauge of carbon steel plate.

Advantages of Different Grades of Carbon Steel Plates

Different grades of carbon steel plates offer various advantages, making them suitable for specific applications. For instance, low-carbon steel plates are known for their excellent ductility and weldability, making them ideal for forming and shaping. On the other hand, high-carbon steel plates provide superior hardness and strength, making them perfect for applications that require wear resistance. Medium-carbon steel plates strike a balance between the two, offering a combination of strength and ductility. By understanding the unique properties of each grade, manufacturers can select the right carbon steel plate to meet their specific needs, ensuring optimal performance and longevity.

Jindalai Steel Group Co., Ltd.: Your Trusted Carbon Steel Plate Producer

When it comes to sourcing high-quality carbon steel plates, Jindalai Steel Group Co., Ltd. stands out as a reputable carbon steel plate producer. With a commitment to excellence and innovation, Jindalai Steel Group has established itself as a leader in the industry. Their extensive range of carbon steel plates, including hot-rolled and cold-rolled options, caters to various applications and industries. By prioritizing quality and customer satisfaction, Jindalai Steel Group ensures that their products meet the highest standards, making them a trusted partner for businesses seeking reliable carbon steel solutions. So, whether you’re in construction, manufacturing, or any other industry, you can count on Jindalai Steel Group for all your carbon steel plate needs.

Post time: Aug-21-2025