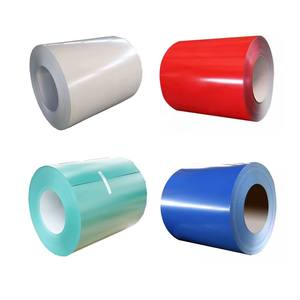

Welcome to the vibrant world of Jindalai Steel Group Co., Ltd., where we take color-coated steel coil to new heights! If you’ve ever wondered how to keep your color-coated steel sheets sharp and crack-free after bending, this is the place for you. Grab your favorite beverage, sit back, and let’s explore the mysteries of color-coated steel, polyurethane edge-banding, and more!

The Dreaded T-Turn: A Mystery That’s Hard to Solve

Imagine this: You’ve just received a shipment of beautiful, color-coated steel coils, ready to be turned into an architectural masterpiece. But wait! You bend them, and suddenly, you’re greeted by the horrifying sight of cracking coatings. What’s going on? This is the infamous “bad T-bend,” a phenomenon that keeps many steelworkers awake at night.

So, what’s the secret to avoiding this disaster? It boils down to a few key factors: pretreatment, coating thickness, and baking temperature. Think of it as a recipe for success! If your pretreatment is like a bad hair day—a mess—then your coating’s adhesion will be as unreliable as a two-legged chair.

Substrate Showdown: Galvanized vs. Zinc-Aluminum-Magnesium

Now, let’s talk substrates! We’ve covered classic galvanized steel, but what about the newer zinc-aluminum-magnesium alloy? Does it require special pretreatment? Spoiler alert: yes! This shiny new substrate has its own unique characteristics, and if you want the coating to stick like peanut butter and jelly, it needs special treatment.

Zinc-aluminum-magnesium substrates are like the goddess of steel, requiring meticulous care. Proper pre-treatment is crucial to ensure your pre-coated steel adheres to the substrate like a loyal friend. So, don’t skimp on prep, or you could end up in trouble!

Chromium-free passivation: The future is bright!

Now, let’s switch gears and talk about the commercialization of chromium-free passivation technology. It’s like a superhero for the steel industry, saving it from the drawbacks of traditional chromate treatment. But how does it compare to its predecessor?

First, chromium-free passivation improves corrosion resistance without the environmental burden of chromates. It’s like trading in your gas guzzler for a sleek electric car—better for the planet and your wallet! However, there’s a catch: while the benefits are clear, the cost may be slightly higher. Still, who wouldn’t want to pay a little more for a greener, longer-lasting product?

Bow Packaging

In short, navigating the world of pre-painted coil and sheet is no easy task. By employing the correct pre-treatment processes, understanding the characteristics of the substrate, and staying abreast of future developments in chrome-free passivation, your pre-painted steel will maintain its aesthetic appeal and superior performance.

So, whether you’re using rock wool composite color-coated steel or the wonders of polyurethane edge banding, remember: accumulated knowledge leads to tremendous progress. If you’re facing coating challenges, consider Jindalai Steel Group Co., Ltd.—a trusted partner ready to help you break through conventions and avoid problems! Cheers to a colorful steel adventure!

Post time: Oct-16-2025