The Copper Conundrum: What’s the Difference?

When it comes to copper plates, you might think they’re all just shiny pieces of metal, but oh boy, are you in for a surprise! Let’s break it down: pure copper, or red copper, is like the classic rock of metals—strong, conductive, and a little flashy. Then we have brass, which is a cool copper-zinc combo that’s great for those who want a little more bling without sacrificing strength. Next up is bronze, the copper-tin hybrid that’s as tough as nails and perfect for those who want to build something that lasts. And let’s not forget cupronickel, the copper-nickel duo that’s all about corrosion resistance. Each of these alloys can be customized through “alloy formulation,” allowing you to tweak strength, corrosion resistance, and even color. So, whether you’re building a ship or just want a fancy door handle, there’s a copper plate for you!

Artistic Effects: More Than Just a Pretty Face

Now, let’s talk about finishes. Sure, you can go for the classic glossy or brushed look, but why stop there? Copper plates can achieve some seriously artistic effects like antique, distressed, and even colored copper! Imagine walking into a room and being greeted by a stunning, aged copper plate that looks like it’s been around since the dawn of time. The secret behind these techniques lies in chemical and physical processes. For instance, patinas can be created through oxidation, giving your copper that rustic charm. And if you’re feeling adventurous, you can even use dyes to create vibrant colors. So, whether you’re a DIY enthusiast or a professional artist, the possibilities are endless!

Rolling with the Times: Modern Production Techniques

Let’s roll into the production side of things! Modern copper plates are produced through rolling processes that are as fascinating as they are efficient. Hot rolling involves heating the metal to a high temperature and then rolling it out, which can lead to a more malleable product. On the other hand, cold rolling is done at room temperature, resulting in a denser and stronger plate. Each method has its perks, and the choice between hot and cold rolling can significantly affect the performance and condition of the final product. So, whether you’re looking for flexibility or strength, the rolling process has got you covered!

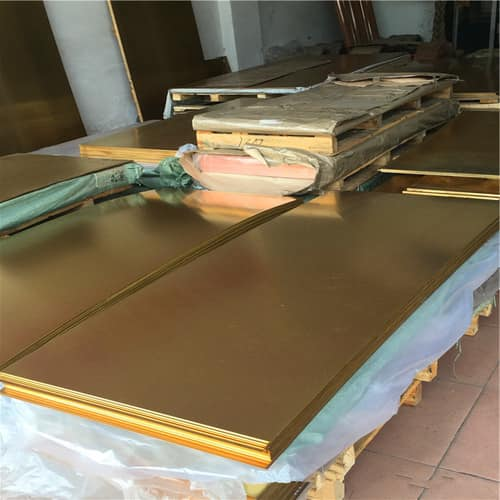

Jindalai Steel Group Co., Ltd.: Your Copper Connection

If you’re on the hunt for high-quality copper plates, look no further than Jindalai Steel Group Co., Ltd. This company knows its stuff when it comes to copper, brass, bronze, and more. With a commitment to quality and innovation, they offer a range of products that cater to all your copper plate needs. Whether you’re a contractor, artist, or just a metal enthusiast, Jindalai has the expertise and products to help you shine. So, why settle for ordinary when you can have extraordinary?

The Final Word: Copper Plates for Every Occasion

In conclusion, copper plates are not just functional; they’re a canvas for creativity and innovation. From the differences in alloys to the artistic finishes and modern production techniques, there’s a whole world of copper waiting to be explored. So, whether you’re looking to build, create, or simply admire, remember that copper plates are the unsung heroes of the metal world. With Jindalai Steel Group Co., Ltd. by your side, you’ll be well-equipped to take on any copper challenge that comes your way!

Post time: Dec-31-2025