Introduction to Galvanized Coil Production

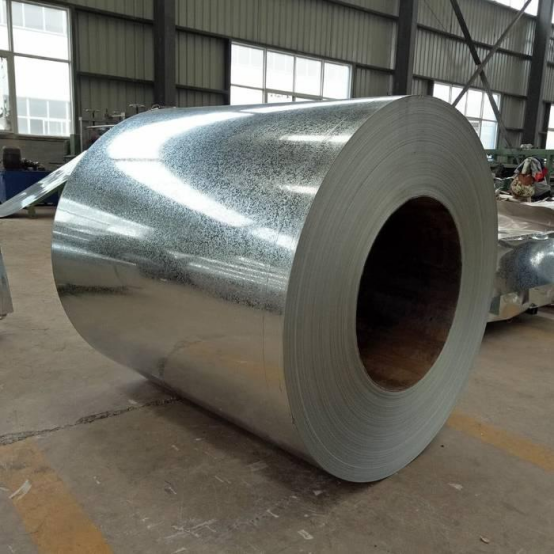

Galvanized coil, particularly galvanized steel coil, is a crucial material in various industries due to its corrosion resistance and durability. Jindalai Steel Group Co., Ltd. specializes in the production of high-quality galvanized steel sheets and coils, ensuring that our products meet the diverse needs of our clients. The production process of galvanized coils involves several key control points, including uncoiling, cleaning, annealing, hot-dip galvanizing, alloying, cooling, and post-treatment. Each step is meticulously monitored to guarantee the highest standards of quality and performance.

Classification Dimensions of Galvanized Steel Products

Besides the classification by process, galvanized steel products can be categorized based on several dimensions. One significant classification is by zinc layer structure, which includes pure zinc, zinc-iron alloy, and zinc-aluminum-magnesium coatings. Each type offers distinct advantages, such as enhanced corrosion resistance or improved mechanical properties. Additionally, surface treatments like passivation, oiling, and fingerprint resistance further differentiate galvanized steel sheets and coils, allowing customers to select products that best suit their specific applications.

Controlling Zinc Flower Morphology and Coating Structure

The morphology of zinc flowers and the coating structure are critical factors that influence the performance of galvanized coils. By adjusting the zinc bath composition—such as incorporating aluminum or magnesium—manufacturers can achieve desired characteristics in the coating. For instance, the addition of aluminum can enhance the coating’s durability, while magnesium can improve its adhesion to the substrate. Furthermore, the parameters of the air knife, which controls the thickness of the zinc layer, and the annealing process can be fine-tuned to ensure optimal coating quality and substrate performance.

Substrate Strength and Its Importance

Another essential classification dimension is substrate strength, which can be categorized into ordinary material and high-strength steel. High-strength galvanized steel coils are increasingly in demand for applications requiring enhanced load-bearing capabilities and structural integrity. Jindalai Steel Group Co., Ltd. offers a range of products that cater to both ordinary and high-strength requirements, ensuring that our clients have access to the right materials for their projects. The careful selection of substrate materials, combined with our advanced galvanizing techniques, results in products that excel in performance and longevity.

The Role of a Reliable Galvanized Coil Supplier

Choosing a reliable galvanized coil supplier is vital for businesses seeking quality and consistency in their materials. Jindalai Steel Group Co., Ltd. prides itself on its commitment to excellence, providing clients with a comprehensive range of galvanized steel products tailored to their needs. Our expertise in the production process, combined with our understanding of classification dimensions, allows us to deliver products that not only meet but exceed industry standards. By partnering with us, customers can be assured of receiving high-quality galvanized coils that enhance their operations and contribute to their success.

In conclusion, the world of galvanized coils is multifaceted, with various classification dimensions and production processes that influence the final product’s quality and performance. Jindalai Steel Group Co., Ltd. stands at the forefront of this industry, offering a diverse range of galvanized steel products designed to meet the evolving needs of our clients.

Post time: Feb-11-2026