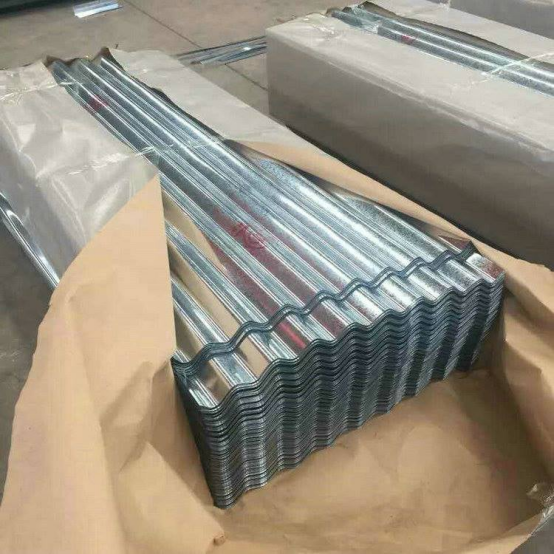

The Marvel of Galvanized Corrugated Sheets

When it comes to roofing materials, the galvanized corrugated sheet stands out as a champion of durability and versatility. Produced by Jindalai Steel Group Co., Ltd., these sheets are not just your average roofing solution; they are engineered to withstand the test of time. The process of galvanization involves coating steel with a layer of zinc, which acts as a sacrificial anode. This means that if the sheet is scratched or damaged, the zinc will corrode first, protecting the underlying steel from rust and decay. It’s like having a bodyguard for your roof—one that takes the hits so your home doesn’t have to!

The Production Process: A Symphony of Precision

The production of galvanized corrugated sheets is a meticulous process that requires attention to detail and adherence to key parameters. First, high-quality steel coils are cleaned and prepped for galvanization. The steel is then immersed in molten zinc, creating a robust protective layer. The corrugation process follows, where the flat sheets are shaped into their iconic wavy form. This geometric design is not just for aesthetics; it significantly enhances the longitudinal stiffness and load-bearing capacity of the sheets. In essence, the galvanized corrugated sheet is a perfect example of how form meets function—thin yet incredibly strong!

The Science Behind Corrosion Protection

Understanding how zinc acts as a sacrificial anode is crucial for appreciating the longevity of galvanized corrugated sheets. When exposed to moisture and air, zinc oxidizes and forms a protective layer of zinc oxide. This layer acts as a barrier, preventing further corrosion of the underlying steel. In a way, zinc is like that friend who always takes the blame for your mischief—noble and self-sacrificing! This unique property ensures that your roofing investment remains intact for years, even in harsh weather conditions.

The Strength of Geometry: Thin Sheets, High Strength

One of the most remarkable features of galvanized corrugated sheets is their geometric shape. The wavy design not only adds visual appeal but also significantly improves the structural integrity of the material. This design allows for a thinner sheet to achieve high strength, making it an ideal choice for various applications, from residential roofing to industrial buildings. It’s a classic case of “less is more”—the thinner the sheet, the lighter the load, yet the stronger the performance. Who knew that a little wave could make such a big difference?

Choosing the Right Supplier: Jindalai Steel Group Co., Ltd.

When it comes to sourcing galvanized corrugated sheets, quality matters. Jindalai Steel Group Co., Ltd. is a trusted supplier known for its commitment to excellence and innovation in the steel industry. With a focus on producing high-quality galvanized corrugated sheets, they ensure that every product meets stringent standards for durability and performance. So, whether you’re a contractor looking for reliable materials or a homeowner planning a renovation, choosing Jindalai Steel Group Co., Ltd. means you’re investing in a product that combines strength, style, and sustainability.

In conclusion, the galvanized corrugated sheet is more than just a roofing material; it’s a testament to engineering ingenuity and protective technology. With its unique production process, corrosion-resistant properties, and structural advantages, it’s no wonder that this sheet has become a staple in modern construction. So, the next time you look up at a roof, remember the unsung hero that keeps it all together—the galvanized corrugated sheet!

Post time: Sep-05-2025