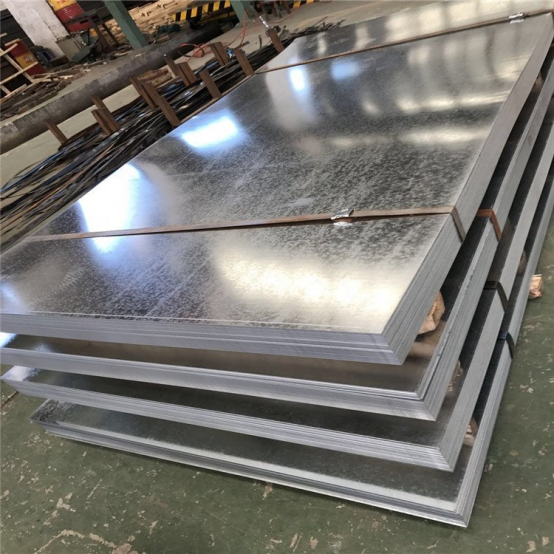

What is Galvanized Sheet?

Ah, the galvanized sheet! It’s like the superhero of the steel world, clad in a shiny coat of zinc to protect it from the dastardly villain known as rust. Galvanized sheets, including hot-dip galvanized thin steel sheets and electro-galvanized thin steel sheets, are steel sheets that have undergone a special coating process to enhance their durability. The hot-dip method involves dipping the steel into molten zinc, creating a thick, robust layer, while the electro-galvanizing process uses electricity to deposit a thinner, more uniform zinc layer. Both methods have their merits, but they share a common goal: keeping your steel sheets rust-free and ready for action!

Hot-Dip vs. Electro-Galvanizing: The Showdown

Now, let’s get down to the nitty-gritty of the fundamental differences between hot-dip galvanizing and electro-galvanizing. Picture this: hot-dip galvanizing is like a hearty meal, providing a thick, protective layer that can withstand the harshest of environments. On the other hand, electro-galvanizing is more like a light snack—great for applications where a thinner coating is sufficient. The choice between the two often boils down to the specific needs of the project. Automakers, container manufacturers, and builders all have their preferences, and understanding these differences can help you make the right choice for your galvanized steel sheets.

Zinc Coating: The Rust Buster

So, how does this magical zinc coating protect our beloved steel sheets from rusting? It’s all about the chemistry, folks! Zinc acts as a sacrificial anode, meaning it will corrode before the underlying steel does. This is like having a trusty sidekick who takes all the hits while the hero remains unscathed. The zinc coating forms a barrier that prevents moisture and oxygen from reaching the steel, effectively keeping rust at bay. So, when you’re selecting galvanized steel sheets, remember that you’re not just choosing a product; you’re investing in a rust-fighting champion!

The Quest for Eco-Friendly Coatings

In the quest for environmentally friendly and high-performance surface treatment technologies, we’ve reached some exciting milestones. Chromium-free passivation and self-lubricating galvanized steel are leading the charge, offering alternatives that are kinder to our planet while still delivering top-notch performance. These innovations are crucial for industries looking to reduce their environmental footprint without sacrificing quality. As we continue to develop these technologies, the future of galvanized steel sheets looks brighter than ever—like a shiny new penny!

Precision in Production: The Art of Coating

Finally, let’s talk about the precision involved in producing galvanized steel sheets. Controlling the thickness and uniformity of the zinc layer is no small feat! Manufacturers use advanced techniques to ensure that every sheet is coated just right. However, common coating defects like incomplete plating and uneven zinc spangle can still rear their ugly heads. These issues often arise from variations in the production process, such as inconsistent temperatures or improper handling. But fear not! With the right quality control measures in place, these defects can be minimized, ensuring that your galvanized steel sheets are nothing short of perfection.

In conclusion, galvanized steel sheets are the unsung heroes of the construction and manufacturing industries. With their rust-resistant properties, eco-friendly advancements, and precision production techniques, they are a reliable choice for anyone looking to build something that lasts. So, the next time you’re in the market for galvanized steel sheets, remember the mighty zinc coating and all the benefits it brings to the table!

Post time: Dec-29-2025