Why Stainless Steel is “Rust-Free”

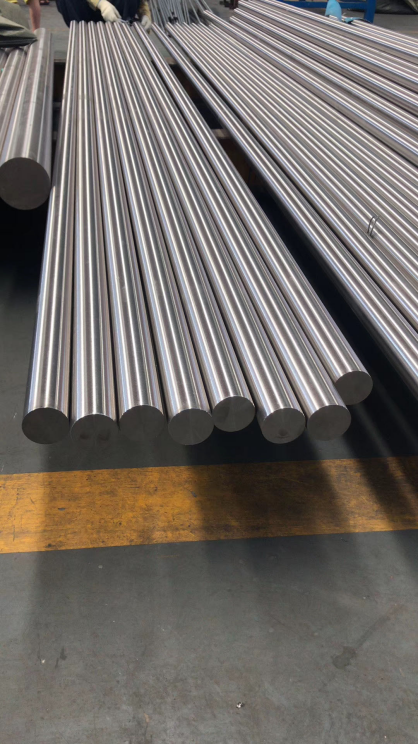

Ah, stainless steel! The metal that promises to be rust-free and deliver on that promise like a loyal dog. But why is that? The secret lies in its composition. Stainless steel bars, like the 304 and 316 grades, contain chromium, which forms a protective layer of chromium oxide when exposed to oxygen. This layer is like a superhero shield, preventing rust and corrosion from wreaking havoc. The 304 stainless steel bar is great for general use, while the 316 stainless steel bar takes it up a notch with added molybdenum for enhanced corrosion resistance, especially in salty environments. So, whether you’re building a boat or a kitchen sink, Jindalai Steel Group Co., Ltd. has got you covered with the right stainless steel bar for the job!

Hot-Rolled vs. Cold-Drawn Bars: The Showdown

Now, let’s talk about the battle of the bars: hot-rolled versus cold-drawn. Hot-rolled bars are like that friend who shows up to a party in sweatpants—functional but not exactly polished. They’re produced at high temperatures, which makes them easier to shape but can leave them with a rough surface finish. On the other hand, cold-drawn bars are the well-dressed attendees, boasting higher precision and a smoother surface finish. They’re perfect for applications where tight tolerances are a must, like in automotive or aerospace industries. So, if you want your project to shine, go for the cold-drawn option!

Surface Treatments: The Makeover Magic

Speaking of shine, let’s dive into surface treatments! Think of pickling, polishing, and sandblasting as the beauty treatments for stainless steel bars. Pickling removes oxides and scales, giving the bar a fresh start. Polishing adds a mirror-like finish that’s not just for looks; it also enhances corrosion resistance. Sandblasting, on the other hand, is like a spa day for your metal, providing a textured finish that can be both functional and aesthetic. Each treatment affects the appearance and performance of the stainless steel bar, so choose wisely based on your project’s needs!

Global Supply and Demand: The Stainless Steel Economy

Now, let’s take a step back and look at the big picture: the global supply and demand for stainless steel bars. The market is booming, with major producers like China, the U.S., and Europe leading the charge. China, in particular, is a heavyweight champion in the stainless steel arena, producing a significant portion of the world’s supply. Trade flows are dynamic, with countries importing and exporting based on demand and production capabilities. So, if you’re in the market for stainless steel bars, keep an eye on the global trends—Jindalai Steel Group Co., Ltd. is ready to meet your needs!

The Bottom Line: Stainless Steel Bars for Every Need

In conclusion, whether you’re looking for a 416 stainless steel bar for its strength, a 304 stainless steel bar for its versatility, or a 316 stainless steel bar for its corrosion resistance, Jindalai Steel Group Co., Ltd. has the perfect solution for you. With a variety of options, surface treatments, and an understanding of the global market, we’re here to help you navigate the world of stainless steel bars. So, let’s raise a toast (with a stainless steel mug, of course) to the unsung heroes of metal—stainless steel bars!

Post time: Jan-09-2026