Introduction to Stainless Steel Plates

Stainless steel plates are a cornerstone of modern manufacturing, providing strength, durability, and resistance to corrosion. Produced by leading manufacturers like Jindalai Iron and Steel Group Co., Ltd., these plates come in various grades and standards, making them suitable for a wide range of applications. Whether you’re constructing a skyscraper or designing kitchen appliances, stainless steel plates are the unsung heroes that hold everything together—quite literally!

Materials, Grades, and Standards

When it comes to stainless steel plates, the materials used are crucial. Typically, these plates are made from a combination of iron, chromium, and nickel, which contribute to their impressive properties. The most common grades include 304 and 316, each offering unique benefits. Grade 304 is known for its excellent corrosion resistance and is often used in kitchen equipment, while grade 316 is favored in marine environments due to its superior resistance to saltwater. Standards such as ASTM A240 ensure that these plates meet specific quality benchmarks, making them reliable for various industrial applications.

Core Characteristics and Advantages

What sets stainless steel plates apart from other materials? For starters, their core characteristics include high tensile strength, low maintenance, and an aesthetic appeal that can’t be ignored. They are also non-reactive, which means they won’t leach harmful substances into food or other materials. The core advantages of using stainless steel plates are numerous: they are easy to clean, resistant to rust and staining, and can withstand extreme temperatures. So, whether you’re grilling burgers or fabricating a spaceship, stainless steel plates have got your back!

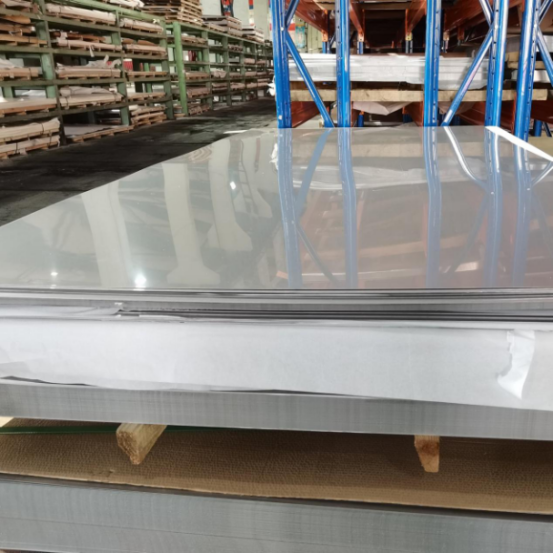

Specifications and Surface Treatments

Stainless steel plates come in various specifications, including thickness, width, and length, allowing for customization based on project needs. Surface treatments also play a significant role in enhancing the performance and appearance of these plates. Options like pickling, passivation, and polishing can improve corrosion resistance and provide a shiny finish that’s perfect for aesthetic applications. So, if you’re looking to impress your guests at a dinner party or just want your industrial equipment to look sharp, consider the surface treatment options available for stainless steel plates.

Application Areas of Stainless Steel Plates

The versatility of stainless steel plates is evident in their wide range of applications. From the food and beverage industry to construction and automotive manufacturing, these plates are everywhere! They are used in everything from kitchen countertops and sinks to structural components in buildings and bridges. Even in the medical field, stainless steel plates are essential for surgical instruments and equipment. So, the next time you enjoy a meal or drive over a bridge, take a moment to appreciate the stainless steel plates that make it all possible!

In conclusion, stainless steel plates are more than just flat pieces of metal; they are vital components that contribute to the functionality and safety of countless products and structures. With manufacturers like Jindalai Iron and Steel Group Co., Ltd. leading the way, the future of stainless steel plates looks brighter than ever. So, whether you’re a manufacturer, designer, or just a curious consumer, remember the importance of these remarkable materials in our everyday lives!

Post time: Sep-07-2025