Understanding Steel Sheet Piles

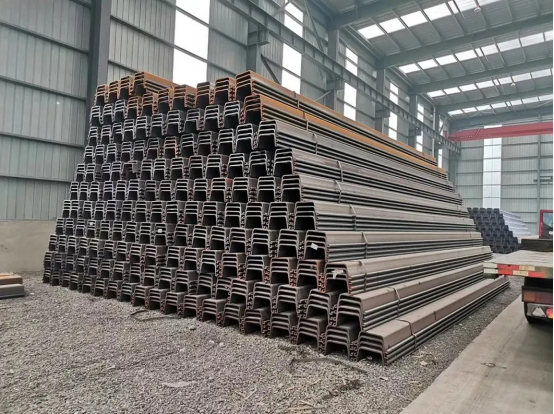

When it comes to construction, steel sheet piles are the unsung heroes of the structural world. These long, slender pieces of steel are driven into the ground to create a barrier, support excavations, and even hold back water. But not all steel sheet piles are created equal! You’ve got your U-shaped, Z-shaped, and straight varieties, each with its own quirks and applications. Think of them as the different personalities in a buddy cop movie—each one has its strengths and weaknesses, and they all come together to get the job done. So, what’s the deal with these shapes? U-shaped piles are great for flexibility, Z-shaped piles offer superior strength, and straight piles are the reliable workhorses of the bunch.

Choosing the Right Steel Sheet Pile

Now, let’s talk about how to pick the right steel sheet pile for your project. It’s not as simple as just grabbing the first one you see at the steel sheet pile wholesale store. You’ve got to consider geological conditions, excavation depth, and the surrounding environment. It’s like dating—what works for one project might not work for another! For instance, if you’re dealing with soft soil, you might want to go with a Z-shaped pile for that extra oomph. On the other hand, if you’re in rocky terrain, a straight pile might be your best bet. So, before you dive into the world of steel sheet piles, make sure you’ve done your homework!

Driving Steel Sheet Piles

Once you’ve selected your steel sheet pile, it’s time to get it into the ground. But how do you do that? There are several methods for driving steel sheet piles, including vibratory hammers, impact hammers, and static pressure pile drivers. Each method has its own set of pros and cons, much like choosing between pizza and tacos for dinner. Vibratory hammers are great for speed and efficiency, while impact hammers pack a punch for tougher materials. Static pressure pile drivers are the quiet, gentle giants of the group, perfect for noise-sensitive environments. Just remember, each method has its own working conditions, so choose wisely!

Noise and Vibration Control

Speaking of noise, let’s chat about the elephant in the room: noise and vibration control. Nobody wants to be that construction site that annoys the entire neighborhood. Luckily, there are ways to minimize the racket. Using vibratory hammers can be quieter than impact hammers, and static pressure pile drivers are practically whispering compared to their counterparts. It’s all about being a good neighbor while still getting the job done. So, when you’re planning your project, don’t forget to factor in how to keep the peace!

Recycling Steel Sheet Piles

Finally, let’s not forget about the environment! Steel sheet piles can be reused, which is fantastic for sustainability. But before you start reusing those bad boys, they need to be inspected, repaired, and rated for safety. Think of it as a health check-up for your steel—nobody wants to use a pile that’s seen better days! Regular inspections ensure that your recycled steel sheet piles are up to snuff and ready for action. So, whether you’re a steel sheet pile manufacturer or just a curious construction enthusiast, remember that safety and sustainability go hand in hand!

In conclusion, steel sheet piles are a vital part of construction, and understanding their types, applications, and maintenance can make all the difference in your project’s success. So, the next time you’re faced with a construction challenge, remember to give a nod to those trusty steel sheet piles!

Post time: Oct-12-2025