Welcome to the world of copperplate engraving! The choices here are as vast as the Grand Canyon, and the applications as diverse as pizza toppings! If you’re still undecided between pure copper engraving, oxygen-free copper engraving (OFC), or brass engraving (H62/H65), then you’ve come to the right place. Jindalai Steel Group is not only a steel company, but also an expert in copper products!

Copper Plates vs. Brass Plates: A Decorative Dilemma

Let’s start with a common question: Is copper or brass more suitable for decorative purposes? If you’re looking for a warm, rustic charm, copper (T2/T3) is definitely your best choice. It’s like a warm, cozy blanket in the world of bronze, adding a touch of elegance to your home décor. On the other hand, if you want a sophisticated yet slightly modern style, then brass is the perfect choice. Its shimmering luster exudes a noble quality, and its golden sheen will make any piece shine!

Industrial Conductivity: Comparison of Copper Plates

If you are in an industrial field and require conductive copper plates, you should avoid decorative copper plates. Instead, choose electrolytic copper plates. These plates are renowned for their superior conductivity and are the best choice for electrical applications. Whether you are wiring new equipment or powering a factory, electrolytic copper plates are ideal!

Outdoor copper plates: Do they require anti-corrosion treatment?

Ah, outdoor life is wonderful! If you’re planning to use copper plates outdoors, you might be wondering if they need anti-corrosion treatment. Spoiler alert: Yes, they do! Outdoor copper plates are like a friend on the beach who needs sunscreen—if not properly cared for, they’ll lose their luster and corrode faster than you might think. Therefore, be sure to choose corrosion-resistant copper plates or apply a protective coating to keep your copper plates looking brand new!

Thin Copper Plates vs. Thick Copper Plates: An Important Decision

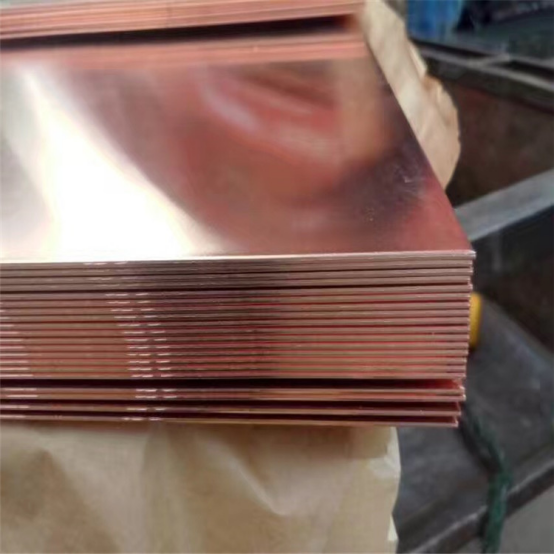

When choosing between thin and thick copper sheets, the key factor is the application scenario. Thin copper sheets are lightweight and flexible, making them ideal for intricate designs or projects with limited space. They are like the gymnasts of the copperware world—light and agile. Thick copper sheets, on the other hand, are robust and durable, ideal for applications requiring high strength and longevity. If your work needs to withstand the test of time (and perhaps even some bumps and knocks), then choose thick copper sheets!

Brushed Copper Plates vs. Mirror Copper Plates: The Debate on Gloss

Finally, let’s discuss the differences between brushed and mirrored copper panels. If you’re looking for a more textured visual effect, brushed copper panels are your best choice. They possess a soft sheen and a rustic feel, adding unique charm to any project. On the other hand, if you want a dazzling, disco-ball-like effect, then mirrored copper panels are the perfect option. They reflect light perfectly, making any space appear more luxurious.

Conclusion: There are many types of copper products!

Dear friends! Whether you need decorative red copper sheets, durable brass sheets, or high-precision copper sheets for industrial applications, Jindalai Steel Group can meet your needs. We offer a wide variety of copper sheets, including thickened copper sheets, patterned copper sheets, and even tin-plated copper sheets. You are sure to find the ideal choice for your next project. Remember, the choice is yours, and we are dedicated to providing you with attentive and meticulous service! We wish you a successful electroplating experience!

Post time: Nov-28-2025