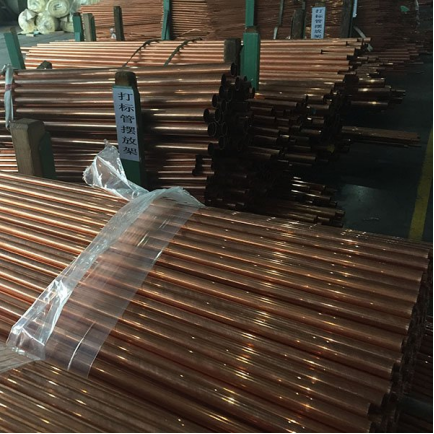

In water supply, drainage, and HVAC systems, the selection of piping materials is crucial. Jindalai Steel Group specializes in all types of copper pipes, including pure copper pipes, oxygen-free copper pipes (OFC), red copper pipes (T2/T3), brass pipes (H62/H65), phosphorus-deoxidized copper pipes, seamless copper pipes, welded copper pipes, thin-walled copper pipes, thick-walled copper pipes, and high-precision copper pipes. This guide will help you understand the complexities of copper pipes and make informed decisions for your projects.

Comparison of seamless copper pipes and welded copper pipes for air conditioning refrigeration

One of the most frequently asked questions we get is: Should I choose seamless copper tubing or welded copper tubing for my air conditioning system? Seamless copper tubing has no joints during manufacturing, making it less prone to leaks and more durable under high pressure. It’s ideal for high-pressure applications, such as refrigeration systems. Welded copper tubing, on the other hand, may be more economical and better suited for low-pressure applications. Ultimately, the choice of copper tubing depends on the specific requirements of your refrigeration system.

Copper and Brass Pipes in Water Supply and Drainage Systems

Another common question is whether to use copper or brass pipes for water supply and drainage systems. Copper pipes are known for their corrosion resistance and long service life, making them a common choice for drinking water systems. Brass pipes, composed of copper and zinc, have excellent strength and are often used for fittings and valves. However, for main water supply lines, copper pipes are usually the preferred choice due to their superior corrosion resistance and ability to maintain water quality.

Thin-walled copper tubes and thick-walled copper tubes: Application scenarios

The application scenarios for thin-walled and thick-walled copper tubing differ significantly. Thin-walled copper tubing is lightweight and flexible, making it ideal for space-constrained applications such as HVAC systems. It is also easier to bend and install. Conversely, thick-walled copper tubing is designed for high-pressure applications and environments with extremely high durability requirements. It is commonly used in industrial applications and heavy-duty piping systems.

Advantages of oxygen-free copper pipes

Oxygen-free copper tubing (OFC) offers numerous advantages over conventional copper tubing. The oxygen-free treatment during manufacturing results in higher purity, thereby enhancing electrical and thermal conductivity. OFC is particularly suitable for applications with extremely high performance requirements, such as audio-visual equipment and medical devices with stringent reliability requirements.

Stability of copper tubes in low-temperature environments

For low-temperature environments, oxygen-free copper tubing is often the best choice to ensure stability. Its excellent thermal conductivity and resistance to thermal expansion make it less prone to cracking or becoming brittle under extremely cold conditions. This characteristic is crucial for refrigeration and cryogenic applications, where maintaining structural integrity is paramount.

Medical Catheter Material Selection

For medical catheters, the choice of copper tubing material is crucial. Phosphorus-deoxidized copper tubing is often recommended due to its excellent biocompatibility and corrosion resistance. These properties ensure the catheter remains safe and effective in medical applications, where hygiene and reliability are extremely important.

In short, choosing the right type of copper tubing is crucial to the success of your project. Whether you need seamless or welded copper tubing for refrigeration, copper or brass tubing for water supply and drainage, or specific types of copper tubing for medical applications, Jindalai Steel Group has the expertise and product range to meet your needs. Contact us today to learn more about our high-quality copper tubing solutions.

Post time: Nov-27-2025