Welcome to the world of riveting galvanized square tubes, where metal meets magic! Whether you’ve explored the mysteries of hot-dip and cold-dip galvanized square tubes before, or you’re just looking for some fun, you’ve come to the right place. Let’s delve into the world of Jindalai Steel Group Co., Ltd. and discover why these tubes are the unsung heroes of the construction and manufacturing industries.

What is galvanized square tube?

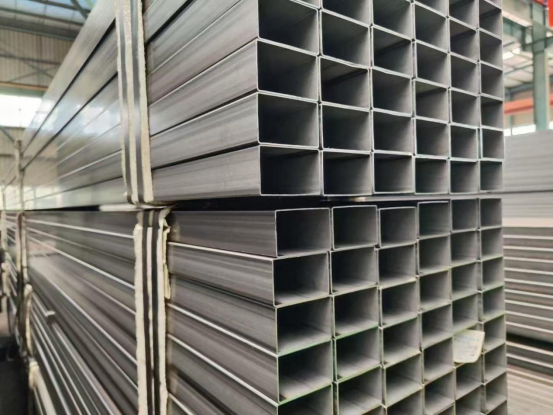

First, what exactly is galvanized square tubing? Imagine a square tubing coated in a protective layer of zinc. This protective layer acts like a superhero’s cape, protecting the tubing from rust and corrosion. Its core structure is typically made of steel, which is then galvanized for enhanced durability. So, if you’re looking for a tubing that’s both weather-resistant and beautiful, you’ve found it!

Hot-dip galvanized vs. cold-dip galvanized square tubes: a showdown

Now, let’s talk about the most critical part: the two most common types of galvanized square tubes: hot-dip galvanized square tubes and cold-dip galvanized square tubes.

**Hot-Dip Galvanized Square Tubing**: This “cool” tubing is dipped in molten zinc, creating a thick, durable coating. Think of it as a “spa day” for metal—dunked in hot zinc for the perfect protective layer. The result? Tubing built to withstand the harshest environments, making it ideal for outdoor applications.

Cold-dip galvanized square pipe: On the other hand, we also have cold-dip galvanized square pipe, which is coated with a thinner layer of zinc through an electroplating process. It’s like a spray of zinc perfume—pleasant, but not as long-lasting as hot-dip galvanized square pipe. While it’s still effective, it’s more suitable for indoor applications or areas less exposed to the elements.

Why do we need to galvanize ordinary square tubes?

You might be thinking, “What’s the big deal about galvanizing regular square tubes?” Well, the main purpose of galvanizing is to prevent rust and corrosion. It’s like coating your metal with a protective film to resist the wear and tear of time. This process solves several pain points, such as:

- Longevity: Galvanized pipes last longer than non-galvanized pipes, saving you money in the long run.

- Maintenance: Less rust means less maintenance. Who doesn’t want to spend less time working with metal?

- VERSATILE: These tubes can be used in a variety of applications, from construction to furniture making.

Reading the specification: What do the numbers represent?

Now, let’s play some numbers. When you see a size like “50 x 50 x 3 mm,” what does it actually mean?

- 50: This is the width of the square tube in millimeters.

- 50: This is the height of the square tube, also in millimeters.

- 3: This is the thickness of the pipe wall in millimeters.

So, in this case, you’re looking at a square tube that’s 50mm wide, 50mm high, and has a wall thickness of 3mm. Pretty simple, right?

in conclusion

In short, galvanized square tubes are the unsung heroes of the metal world. They’re not only durable but also remarkably resistant to the elements. Whether you’re looking for hot-dip or cold-dip galvanized square tubes, Jindalai Steel Group Co., Ltd. has you covered. So, the next time you need a reliable metal solution, remember the magic of galvanized square tubes! They’re more than just pipes; they’re your metal’s best friend.

Post time: Oct-20-2025