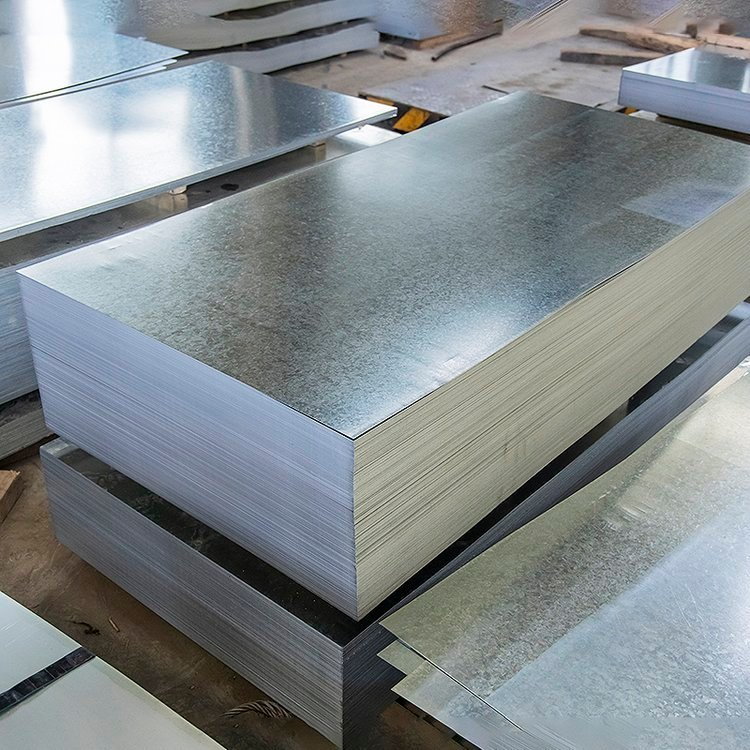

When it comes to the world of construction and manufacturing, the term “galvanized sheet” often pops up, and for good reason. Galvanized steel sheets, particularly those produced by reputable manufacturers like Jindalai Steel Group Co., Ltd., are essential materials in various industries. But what exactly are galvanized sheets, and how do they differ based on their production processes? In this blog, we will explore the nuances of galvanized steel sheets, including the differences between hot dip galvanized steel sheets and hot rolled galvanized sheets, as well as the implications of zinc layer thickness and surface characteristics.

To kick things off, let’s clarify what galvanized sheets are. Essentially, these are steel sheets coated with a layer of zinc to protect them from corrosion. The process of galvanization can be done in several ways, with hot dip galvanization being one of the most common methods. In this process, steel sheets are submerged in molten zinc, creating a robust protective layer. On the other hand, hot rolled galvanized sheets are produced by rolling the steel at high temperatures before applying the zinc coating. Each method has its own set of advantages, and the choice often depends on the intended application of the galvanized sheet.

Now, let’s talk about the applications of galvanized sheets. The thickness of the zinc layer plays a crucial role in determining where and how these sheets can be used. For instance, a thicker zinc layer is ideal for outdoor applications where exposure to moisture and harsh weather conditions is a concern. Conversely, thinner layers may suffice for indoor applications where the risk of corrosion is minimal. Understanding the specific requirements of your project can help you choose the right galvanized steel sheet, ensuring durability and longevity.

One fascinating aspect of galvanized sheets is the size of the zinc flowers on their surface. These “flowers” are the crystalline structures formed during the galvanization process, and their size can significantly impact the adhesion of subsequent coatings. Large zinc flowers may create a rough surface that can enhance adhesion for paints and other coatings, while smaller flowers might lead to a smoother finish but could compromise adhesion. This is a critical consideration for manufacturers like Jindalai Steel Group Co., Ltd., who aim to produce high-quality galvanized steel sheets that meet the diverse needs of their clients.

In conclusion, understanding the differences between galvanized sheets produced through various processes, their applications based on zinc layer thickness, and the effects of zinc flower size on coating adhesion is essential for anyone involved in construction or manufacturing. Whether you’re a seasoned professional or a DIY enthusiast, knowing these details can help you make informed decisions when selecting galvanized steel sheets. So, the next time you find yourself in need of galvanized sheets, remember to consider the production method, application requirements, and surface characteristics to ensure you choose the best product for your needs. Happy building!

Post time: Aug-03-2025