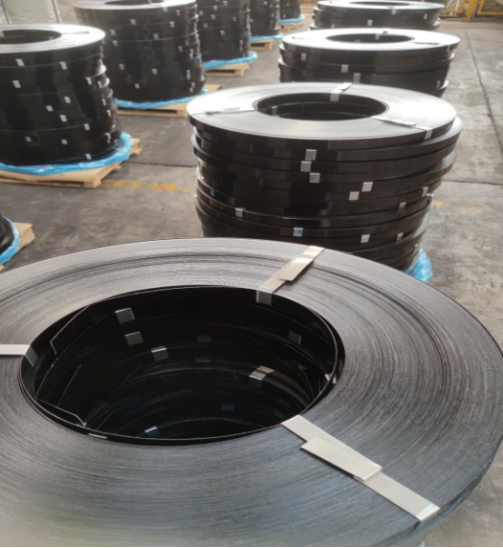

When choosing the right galvanized steel strip for your project, understanding the different types and their applications is crucial. Jindalai Steel Group Co., Ltd. specializes in providing high-quality galvanized steel strip, including continuous hot-dip galvanized steel strip, precision galvanized steel strip, and stamping-grade galvanized steel strip. This blog will explore the key differences between hot-dip galvanized steel strip (HDG), cold-dip galvanized steel strip (EG), and alloy galvanized steel strip (GA), and how to choose the right product for your needs.

Key Differences in Galvanized Steel Strip

1. Hot-dip galvanized steel strip (HDG steel strip): This type of galvanized steel strip is made by immersing steel in molten zinc, resulting in a thick and robust coating. Hot-dip galvanized steel strip is renowned for its superior corrosion resistance and durability, making it ideal for outdoor applications and high-humidity environments.

2. Cold-dip galvanized steel strip (EG steel strip): Unlike hot-dip galvanized steel strip, cold-dip galvanized steel strip is galvanized through an electroplating process. This method produces a thinner coating than hot-dip galvanizing. While cold-dip galvanized steel strip offers some corrosion resistance, it is best suited for indoor applications or environments with extremely low humidity.

3. Alloy Galvanized Steel Strip (GA Steel Strip): Alloy galvanized steel strip is made by adding alloying elements to the zinc layer, thereby enhancing the adhesion and corrosion resistance of the steel. This type of galvanized steel strip is particularly suitable for applications requiring higher durability and service life.

Choose galvanized steel strips with or without patterns.

When choosing between patterned and unpatterned galvanized steel strips, consider both the aesthetic and functional requirements of your project. Patterned steel strips offer additional grip and surface texture, making them suitable for applications requiring high slip resistance. Unpatterned steel strips, with their smooth surface, may be more suitable for decorative or architectural applications.

Common Materials for Galvanized Steel Strip

Galvanized steel strip is typically made from low-carbon steel, offering excellent formability and strength. The galvanized layer enhances its corrosion resistance, thus ensuring the product’s service life. Jindalai Steel Group Co., Ltd. strictly adheres to international standards such as ASTM A123, ASTM A653, and ISO 1461 to ensure our products meet the highest quality and safety requirements.

Selecting Zinc Coating Thickness

The thickness of the galvanized coating is a key factor determining the performance of galvanized steel strip. Recommended coating thickness standards vary depending on the intended application. For example, indoor applications typically recommend a coating thickness of at least 45 micrometers, while outdoor applications may require a coating thickness of 85 micrometers or more to ensure adequate corrosion protection.

In summary, choosing the right galvanized steel strip requires understanding the differences between hot-dip galvanizing, cold-dip galvanizing, and alloy galvanizing, and considering factors such as pattern, material composition, and zinc layer thickness. Jindalai Steel Group Co., Ltd. is committed to providing customers with customized, high-quality galvanized steel strips to meet their specific needs. Whether you need precision galvanized steel strips for manufacturing or stamping-grade galvanized steel strips for construction, we have the expertise and extensive product range to support your projects. Contact us today to learn more about our products and how we can help you choose the galvanized steel strip best suited to your requirements.

Post time: Feb-05-2026