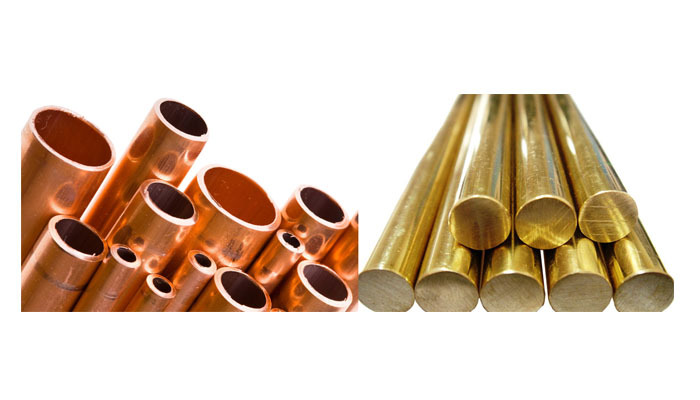

Copper is pure and single metal, every object made of copper exhibit the same properties. On the other hand, brass is an alloy of copper, zinc, and other metals. The combination of several metals means that there is no single foolproof method to identify all brass. However, we are going to discuss the methods of how to differentiate brass from copper. These methods are stated below:

● Color Identification

Clean the two metals to be differentiated. Both copper and brass develop a patina with time. This patina is mostly greenish. In a situation where the original metal is visible, try the cleaning technique of brass. While this technique works for both metals, use commercial copper and brass cleaning products to be on the safer side.

Place the metal under white light. In this case, if the metals to be identified is polished, then false light may be seen as a result of reflected light. Another way to go around this is by looking at it under a white fluorescent light bulb or the sunlight. For identification please avoid the yellow incandescent bulb.

Identify the reddish color of copper. It is pure metal with a reddish-brown appearance.

Inspect for the yellow brass. Brass is made up of copper and zinc. The varying proportion of zinc in brass produce different colors. Mostly, the common brass used exhibited muted yellow color or a yellow-brown appearance which is similar to bronze. Another type of brass is greenish-yellow in appearance, while this alloy is called the “the gilding metal”. It has limited applications in ammunition and decoration.

Inspect for red or orange brass. When brass alloy metal is composed of at least 85% copper, it may look reddish-brown or orange. This type of brass is used mostly in decorative fasteners, jewelry, and plumbing. So, any hint of yellow, orange, or gold coloration depicts the metal is brass and not copper.

Identifying other brass. High zinc content brass can look bright gold, white, grey, or even yellowish-white. The alloys in these categories are not common since they are not machinable. However, you can find their application in jewelry.

● Other Method of Identification

Use of sound: since copper is a soft metal, it produces a muted round sound when striking against another component. A test carried out in 1987 described copper’s sound as ‘dead’ while brass was said to emit a clear ringing note’. Judging with this method may be tough without experience. The good news is that learning this method over time is useful especially for an antique or scrap collection hobby. This method works best for a solid method.

Choosing the right metal for your project

The selection of the right metal type for an application is a critical thing to note when it comes to designing and manufacturing high-quality products or parts. Although both metals (Copper & Brass) provide thermal and electrical conductivity, strength, corrosion resistance, and more, they each possess distinct differences.

While each of Copper and Brass is durable, they do not have the same level of flexibility. In selection for your project, pure oxygen-free copper exhibit the greatest flexibility, conductivity, and ductility while bronze offer machinability.

In terms of general utility, brass is mostly considered and most suitable for general applications. It is easy to cast, relatively inexpensive, and malleable with low friction. Brass is most applicable for decorative components and for metal pieces that people come in contact with on a daily basis such as a doorknob. It is applicable in the food processing industry for food grades that need to be protected from microbial and bacterial infestation.

Summary: Brass vs. Copper, Which One is Best for Your Project?

Understanding the respective properties of brass and copper is crucial to selecting the best material for your projects. It helps to provide answers to the age-old question of "which is better between copper and brass." Our detailed information will make you realize that both metals are more valuable in their application. In conclusion, both metals are better for their specific applications.

If you need machining brass parts or machining copper parts, JINDALAI is the best supplier you can trust, I am happy to hear from you!

HOTLINE: +86 18864971774 WECHAT: +86 18864971774 WHATSAPP: https://wa.me/8618864971774

EMAIL: jindalaisteel@gmail.com sales@jindalaisteelgroup.com WEBSITE: www.jindalaisteel.com

Post time: Dec-19-2022