What is a Galvanized Iron Pipe or GI Pipe?

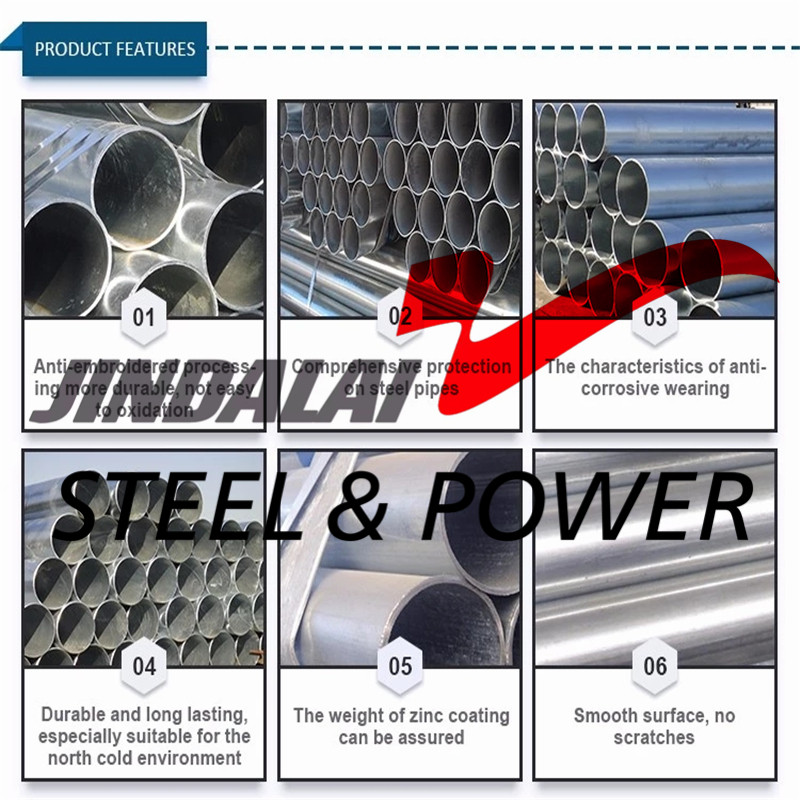

Galvanized iron pipes (GI pipes) are pipes that have been coated with a layer of zinc to prevent rusting and increase its durability and lifespan. This protective barrier also resists corrosion and wear and tear from constant exposure to harsh environmental elements and indoor humidity.

Durable, versatile and low-maintenance, GI pipes are ideal for a number of heavy-duty industrial applications.

GI pipes are commonly used for

● Plumbing - Water supply and sewage systems use GI pipes as they can withstand harsh weather conditions and are long-lasting, able to last for 70 years depending on application.

● Gas and oil transmission - GI pipes are corrosion-resistant or can be applied with anti-corrosion coating, allowing them to last for up to 70 or 80 years despite constant use and extreme environment conditions.

● Scaffolding and railing - GI pipes can be used to create scaffolding and protective railings in construction sites.

● Fencing - A GI pipe can be used to create bollards and boundary marks.

● Agriculture, marine and telecommunications - GI pipes are designed to be resilient against constant use and consistent exposure to changing environments.

● Automotive and aerospace application - GI pipes are lightweight, rust-resistant and malleable, making them staple materials when constructing aircrafts and land-based vehicles.

What are the advantages of GI Pipe?

GI pipes in the Philippines have been used primarily as the preferred tubing material for indoor and outdoor applications. Their benefits include:

● Durability and longevity – GI pipes boast a protective zinc barrier, which prevents corrosion from reaching and penetrating the pipes, thereby making it resistant to wear and tear and adding to its lifespan.

● Smooth finish – Galvanization not only makes GI pipes rust-resistant, but scratch-resistant as well, resulting in a smoother and more attractive exterior.

● Heavy-duty applications – From irrigation system development to large-scale building constructions, GI pipes are the most ideal for piping, in terms of cost-effectiveness and maintenance.

● Cost-effectiveness – Considering its quality, life span, durability, easy installation and handling, and maintenance, GI pipes are generally low-cost in the long run.

● Sustainability – GI pipes are used everywhere, from cars to houses to buildings, and can be continuously recycled thanks to their durability.

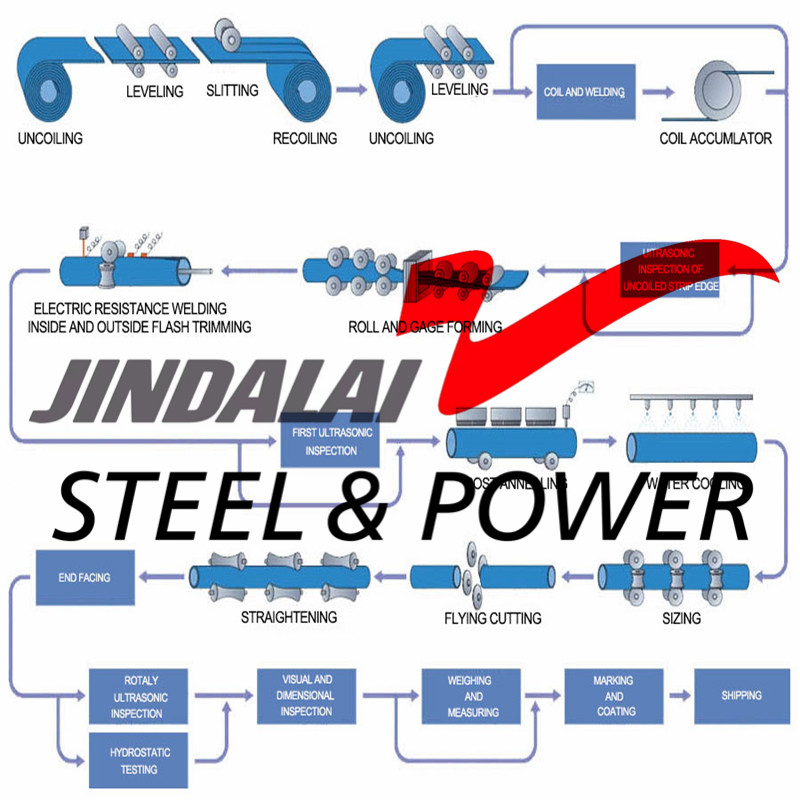

About Our Quality

A. No damage, no bent

B. No burrs or sharp edges and no scraps

C. Free for oiled&marking

D. All goods can be checked by third party inspection before shipment

Detail drawing

-

Galvanized Square Pipe/Gi Tube

-

Galvanized Steel Wire/ GI Steel Wire

-

Hot Dip Galvanized Steel tube/GI Pipe

-

Prime Quality DX51D Astm A653 GI Galvanized Ste...

-

Professional Manufacturer Ppgi Coils for Roofin...

-

Galvanized Oval Wire

-

Galvanized Corrugated Roofing Sheet

-

ASTM A653 Z275 Galvanized Steel Coil China Factory

-

Galvanized Steel Roofing Sheets Price

-

Hot dipped galvanized steel wire