Overview of Nickel Alloy 201 Plate

Nickel Alloy 201 Plates (Nickel 201 Plates) are relatively perfect for coastal, marine, and hostile industrial atmospheres. Nickel Alloy 201 Sheets (Nickel 201 Plates) are reasonably Cost Effective and are Accessible in widespread range of sizes. Meanwhile, we as well offer these UNS N02201 Sheets Plates / WNR 2.4068 Sheets Plates and UNS N02201 Sheets Plates / WNR 2.4068 Sheets Plates in customized thicknesses and sizes as per the précised requirements given by our valuable customers in international quality of standards.

These are also referred as UNS N02201 Round Bars and WNR 2.4066 Round Bars. Nickel 201 Round Bars (Nickel Alloy 201 Bars) can be electroplated and are effortlessly welded, making them appropriate for use in industries where very much high and low temperatures come into drama. Nickel 201 Rods (Nickel Alloy 201 Rods) provides extremely ductile mechanical features all over an extensive temperature range. Meanwhile, we as well offer the same in customized thicknesses and sizes as per the precise requirements given by our valuable customers in international quality of standards.

Advantages of Nickel Alloy 201 Plate

● Corrosion & oxidation resistant

● Ductility

● Brilliant polish

● Excellent machine strength

● High creep resistance

● High temperature strenght

● Excellent mechanical properties

● Low gas content

● Low vapor pressure

Magnetic properties

These properties and its chemical composition make Nickel 200 fabricatable and highly resistant to corrosive environments. Nickel 201 is useful in any environment below 600º F. It is highly resistant to corrosion by neutral and alkaline salt solutions. Nickel alloy 200 also has low corrosion rates in neutral and distilled water. This nickel alloy can be hot formed to any shape and formed cold by all methods.

Nickel Alloy 201 Plates Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

| Nickel Alloy 201 | 2.4068 | N02201 | NW 2201 | - | NA 12 | НП-2 | Ni 99 |

Chemical Composition

| Element | Content (%) |

| Nickel, Ni | ≥ 99 |

| Iron, Fe | ≤ 0.40 |

| Manganese, Mn | ≤ 0.35 |

| Silicon, Si | ≤ 0.35 |

| Copper, Cu | ≤ 0.25 |

| Carbon, C | ≤ 0.15 |

| Sulfur, S | ≤ 0.010 |

Physical Properties

| Properties | Metric | Imperial |

| Density | 8.89 g/cm3 | 0.321 lb/in3 |

| Melting point | 1435-1446°C | 2615-2635°F |

Mechanical Properties

| Properties | Metric | Imperial |

| Tensile strength (annealed) | 462 MPa | 67000 psi |

| Yield strength (annealed) | 148 MPa | 21500 psi |

| Elongation at break (annealed prior to test) | 45% | 45% |

Thermal Properties

| Properties | Metric | Imperial |

| Thermal expansion co-efficient (@20-100°C/68-212°F) | 13.3 µm/m°C | 7.39 µin/in°F |

| Thermal conductivity | 70.2 W/mK | 487 BTU.in/hrft².°F |

Fabrication and Heat Treatment

Nickel 201 alloy can be shaped through all hot working and cold working practices. The alloy can be hot worked between 649°C (1200°F) and 1232°C (2250°F), with heavy forming carried out at temperatures above 871°C (1600°F). Annealing is performed at temperature between 704°C (1300°F) and 871°C (1600°F).

Applications

Off-Shore Oil Drilling Companies

Aeronautical

Pharmaceutical Equipment

Power Generation

Chemical Equipment

Petrochemicals

Sea Water Equipment

Gas Processing

Heat Exchangers

Specialty Chemicals

Condensers

Pulp and Paper Industry

JINDALAI’S Nickel 201 alloy to countries like UAE, Bahrain, Italy, Indonesia, Malaysia, United States, Mexico, Chine, Brazil, Peru, Nigeria, Kuwait, Jordan, Dubai, Thailand (Bangkok), Venezuela, Iran, Germany, UK, Canada, Russia, Turkey, Australia, New Zealand, Sri Lanka, Vietnam, South Africa, Kazakhstan & Saudi Arabia.

Detail drawing

-

Nickel Alloy Plates

-

Nickel 200/201 Nickel Alloy Plate

-

SA387 Steel Plate

-

4140 Alloy Steel Plate

-

430 BA Cold Rolled Stainless Steel Plates

-

Customized Perforated 304 316 Stainless Steel P...

-

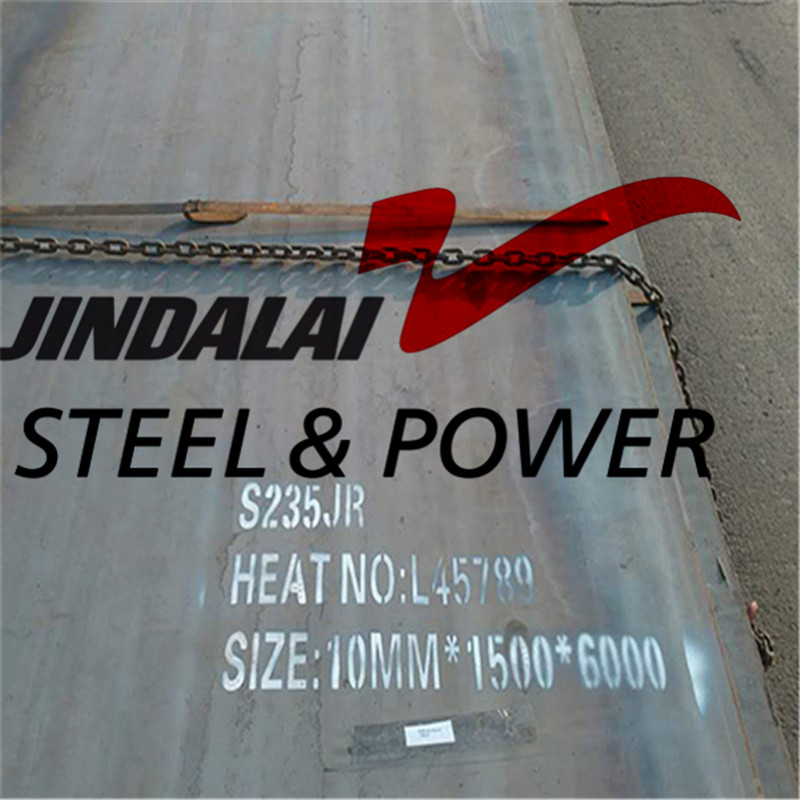

S235JR Carbon Steel Plates/MS Plate

-

ST37 Steel Plate/ Carbon Steel Plate

-

SA516 GR 70 Pressure Vessel Steel Plates

-

S355 Structural Steel Plate

-

Marine Grade CCS Grade A Steel Plate

-

Hot Rolled Galvanized Checkered Steel Plate

-

ASTM A36 Steel Plate

-

A 516 Grade 60 Vessel Steel Plate