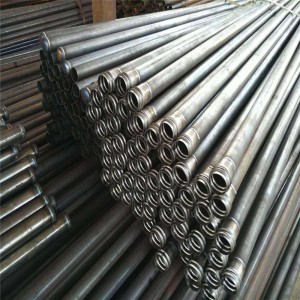

Overview of Crosshole Sonic Logging (CSL) Pipe

CSL tubes are normally produced with 1.5- or 2-inch diameters, filled with water, and are threaded with watertight caps and couplers. This ensures the tubes comply with the specifications of American Society of Testing and Materials (ASTM)-A53 Grade B, along with mill test reports (MTR). These tubes are usually attached to the rebar cage that reinforces the drilled shaft.

Specification of Cross Hole Sonic Logging (CSL) Tubes

| Name | Screw/Auger Type Sonic Log Pipe | |||

| Shape | No.1 pipe | No.2 pipe | No.3 pipe | |

| Outer diameter | 50.00mm | 53.00mm | 57.00mm | |

| Wall thickness | 1.0-2.0mm | 1.0-2.0mm | 1.2-2.0mm | |

| Length | 3m/6m/9m, etc. | |||

| Standard | GB/T3091-2008, ASTM A53, BS1387, ASTM A500, BS 4568, BS EN31, DIN 2444, etc | |||

| Grade | China Grade | Q215 Q235 According to GB/T700;Q345 According to GB/T1591 | ||

| Foreign Grade | ASTM | A53, Grade B, Grade C, Grade D, Grade 50 A283GRC, A283GRB, A306GR55,etc | ||

| EN | S185, S235JR, S235J0, E335, S355JR, S355J2, etc | |||

| JIS | SS330, SS400, SPFC590,etc | |||

| Surface | Bared, Galvanized, Oiled, Color Paint, 3PE; Or Other Anti-corrosive Treatment | |||

| Inspection | With Chemical Composition and Mechanical Properties Analysis; Dimensional and Visual Inspection, Also With Nondestructive Inspection. |

|||

| Usage | Used in the sonic testing applications. | |||

| main market | Middle East, Africa, Asia and some European country, America, Australia | |||

| Packing | 1.bundle 2.in bulk 3.plastic bags 4.according to client's requirement |

|||

| Delivery time | 10-15 days after the order be confirmed. | |||

| Payment Terms | 1.T/T 2.L/C: at sight 3.Westem Union |

|||

Applications of Cross Hole Sonic Logging (CSL) Tubes

The tubes are usually attached to the reinforcement cage along the full length of the shafts. After concrete has been poured, the tubes are filled with water. In CSL, a transmitter emits an ultrasonic signal in one tube and the signal is sensed some time later by the receiver in another sonic tube. Poor concrete between the sonic tubes will delay or disrupt the signal. The engineer lowers the probes to the bottom of the shaft and moves the transmitter and receiver upward, until the entire shaft length is scanned. The engineer repeats the test for each pair of tubes. The engineer interprets data in the field and later reprocesses it in the office.

JINDALAI’s CSL pipes are composed of steel. Steel pipes are typically preferred over PVC pipes because PVC material can debond from concrete due to heat from the concrete hydration process. Debonded pipes often lead to inconsistent concrete test results. Our CSL pipes are frequently used as a quality assurance measure to guarantee the stability of drilled shaft foundations and structural integrity. Our customizable CSL pipes can also be used to test slurry walls, auger cast piles, mat foundations, and mass concrete pours. This type of testing can also be performed to determine the integrity of a drilled shaft by finding potential problems like soil intrusions, sand lenses, or voids.

Advantages of Cross Hole Sonic Logging (CSL) Tubes

1.Fast and easy installation by worker.

2.Push-fit assembly.

3.No welding required at jobsite.

4.No equipment required.

5.Easy fixing to rebar cage.

6.Push-fit mark to ensure full engagement.

-

A53 Grouting Steel Pipe

-

API5L Carbon Steel Pipe/ ERW Pipe

-

ASTM A53 Grade A & B Steel Pipe ERW Pipe

-

ASTM A536 Ductile Iron Tube

-

A106 Crosshole Sonic Logging Welded Tube

-

ASTM A53 Crosshole Sonic Logging (CSL) Welded Pipe

-

SSAW Steel Pipe/Spiral Weld Pipe

-

A106 GrB Seamless Grouting Steel Pipes for Pile

-

R25 Self-Drilling Hollow Grout Injection Anchor...