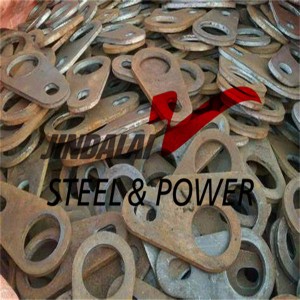

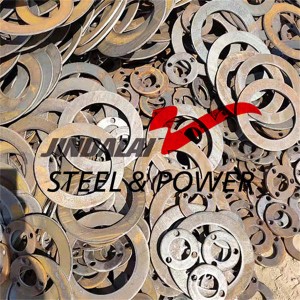

Specification Of Metal Stamping Parts

| Product Name | Customized Metal Stamping Parts |

| Material | Steel, Stainless steel, Aluminum, Copper, Brass, etc |

| Plating | Ni Plating, Sn Plating, Cr Plating, Ag Plating, Au Plating, electrophoretic paint etc. |

| Standard | DIN GB ISO JIS BA ANSI |

| Design file format | Cad, jpg, pdf etc. |

| Major Equipments | --AMADA Laser cutting machine --AMADA NCT punching machine --AMADA bending machines --TIG/MIG welding machines --Spot welding machines --Stamping machines (60T ~ 315T for progress and 200T~600T for robot transfer) --Riveting machine --Pipe cutting machine --Drawing mill --Stamping tools make maching(CNC milling machine, Wire-cut, EDM, Grinding machine) |

| Press machine tonnage | 60T to 315(Progress)and 200T~600T (Robot treansfer) |

What Is Stamped Parts?

Stamping Parts-Stamping is a forming process that relies on presses and dies to apply external forces to materials such as plates, strips, tubes and profiles to produce plastic deformation or separation to obtain workpieces of the required shape and size (stamped parts). The blanks for stamping are mainly hot-rolled and cold-rolled steel plates and strips. Thanks to the use of precision dies, work pieces can be produced with micron-level precision and with high repeatability and uniformity of specifications, allowing for the stamping of holes and bosses, etc.

Stamped parts are generally commonly used in various industries such as automotive, aerospace and medical to provide a variety of customised parts. Stamped metal parts are an effective and affordable way to meet the requirements for high volume manufacturing of customised metal parts, which typically meet the requirements of.

Features Of Metal Stamping

Stamped parts have high dimensional accuracy and the same moulded parts are uniform in size. They can meet the general assembly and use requirements without further mechanical processing.

Cold stamped parts are generally not subject to any cutting process or require only a small amount of cutting process.

In the stamping process, the surface of the material is not damaged, so it has good surface quality and a smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating, powder spraying and other surface treatment.

Stamped parts are manufactured by stamping on the premise that the material is not consumed much. The parts are light in weight and have good stiffness, and after the plastic deformation of the sheet, the internal structure of the metal is improved, so that the strength of the stamped parts is increased.

Compared with castings and forgings, stamped parts have the characteristics of thinness, uniformity, lightness and strength. Stamping can produce work pieces with reinforcing bars, ribs, undulations or flanges that are difficult to manufacture by other methods, in order to improve their rigidity.

Detail Drawing