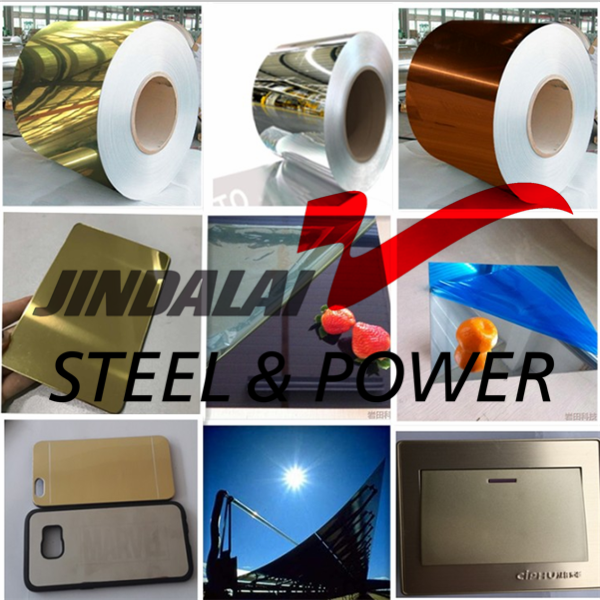

Overview of Polished Aluminum Plate:

Mirror aluminum plate, named after its smooth surface that can produce a mirror effect, is a widely used and environmentally friendly material. We can see its presence in various fields, including indoor and outdoor decoration, kitchen supplies, furniture and lighting fixtures, electronic product casings, automotive interior and exterior decoration, lighting reflector panels, solar thermal reflective materials, signage, logos, luggage, jewelry boxes, and more. It is affordable, durable, beautiful, glossy, and not easy to oxidize, with a long service life, so it is highly sought after in the market.

Specification of Mirror Polished Aluminum Plate:

| Mirror Polished Aluminum Plate | ||

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc | |

| Grade | 1000 Series, 2000 Series, 3000Series, 4000 Series, 5000 Series, 6000 Series,

7000 Series, 8000 Series, 9000 Series |

|

| Size | Thickness | 0.05-50mm, or customer required |

| Width | 10-2000mm, or according to customer’s required | |

| Length | 2000mm, 2440mm or as reuqired | |

| Surface | Color Coated, Embossed, Brushed, Mirror Polished, Anodized,etc | |

| Temper | O, F, H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H36, H38, H111, H112, H321, T3, T4, T5, T6, T7, T351, T451, T651, T851 | |

| OEM service | Perforated, Cutting special size, Doing flatness, Surface treatment, etc | |

| Delivery Time | Within 3 days for stock size,10-15 days of production | |

| Application | Construction filed, Ships building industry, Decoration, Industry, Manufacture, Machinery and hardware fields, etc | |

| Sample | Free and available | |

| Package | Export standard package: bundled wooden box, suit for all kinds of transport,or be required | |

Features of Mirror Polished Aluminum Plate:

1.Highly reflective rate&durable, long impression available

2.Faithful reproduction capacity, result at clear images

3.Surface smoothness and easy cleaning

4.Flexible suspension system makes each ceiling tile easily installed and disconnected

5.Easy to match lamps or other ceiling parts

6.Surface color can be stable for 10 years by indoor use

7.Inflammable and fire resistant, waterproof, moisture proof, Sound and heat insulated, corrosion resistant,easy maintenance

8.Light weight and excellent decorative performance

Maintenance Methods for Mirror Polished Aluminum Plate:

Step 1: To thoroughly rinse the surface of the mirror aluminum plate with a large amount of water;

Step 2: Dilute the detergent with water and soak a softer cloth inside, then gently wipe the surface of the aluminum plate with a damp cloth;

Step 3: After wiping, rinse the board surface with a large amount of water again and rinse away any dirt on it with water;

Step 4: After flushing, check if there are any areas that have not been cleaned thoroughly. You can choose to focus on cleaning with detergent;

Step 5: Rinse the surface of the aluminum plate once and rinse off all the detergent on it.

Special width and length inquiries are also welcomed. Non-stock custom mirror polished aluminum panels with color painting is available, call for mill minimums and details. Please Email jindalaisteel@gmail.com for all stock finishes, colors, gauges, and widths. Mill Certificate of Specifications obtainable upon request.

Detail drawing